Ingredients:

- 6 pounds pale LME

- 0.5 pounds English crystal 40L malt specialty grains

- 1.5 oz Palisade hops (boiling)

- 0.5 oz Palisade hops (finishing)

- 6 grams Muntons active brewing yeast (1 packet)

I ended up following an amalgam of The Cellar's general instructions for their mini-brewery kit, The Cellar's instructions for the red ale recipe, and John Palmer's How To Brew instructions.

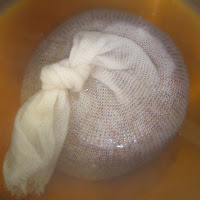

Steeped grains in muslin bag in 2 quarts boiling water (off heat) for 15 min. Delicious grain aroma!

Brought 2.5 gallons of water to boil in 16 quart pot, which I initially thought was a 20 quart pot. Added steeping liquid and rinsed grain with another quart of hot water. Began stirring in LME and it foamed dramatically. Figured I was going to have boilover problems for sure, so removed 3 quarts to second pot. Distributed LME between the two and did some blending to get a fairly homogenous mix.

Boiled moderately for 55 minutes with bittering hops, then 5 with finishing hops. Not sure whether hot break had occurred before I was done mixing the LME and added the bittering hops. It certainly had occurred very shortly after.

I was going to use the wort chiller I borrowed from Joe, but it is too big for the 16 quart pot.

Cooled in ice bath. Much evaporation during boiling -- probably down from 3.25 gallons to well under 3. Starting a good whirlpool makes an enormous difference in heat transfer, with the ice responding rapidly.

Cooled in ice bath. Much evaporation during boiling -- probably down from 3.25 gallons to well under 3. Starting a good whirlpool makes an enormous difference in heat transfer, with the ice responding rapidly.

Rehydrated the yeast in boiled 80-ish degree water in a sanitized glass jar. Swirled to mix after about 15 minutes, shook vigorously just before pitching.

Wort was down to 100 after 30 minutes in the sink. Added two gallons of cold tap water in fermenter and poured wort, bringing temperature down to 80. Poured back and forth between fermenter and kettle several times. Pitched yeast. Poured again. Topped off to 1 inch over 5 gallon mark.

Original specific gravity measured at 1.048 at 67 degrees. Adjusted for the hydrometer's 60 degree calibration that's about 1.049.

Tasted the wort and detected noticeable bitterness and slight hoppiness. It is lightly sweet. This is much more like I think it should be, compared to the first unhopped attempt. Quite a bit of crud in suspension. Next time might want to use some technique to minimize, but I think this will have settled by the time primary fermentation is complete and I transfer to the carboy.

Possible grievous errors:

- May have aerated the wort while it was hot by pouring it from the small pot into the big pot and then by stirring it twice while it was cooling. See Palmer pp 71 - 72 for why this was bad.

- May not have allowed sanitizer to work long enough on thermometers used for yeast and wort.

- Dropped the small thermometer into the fermenter entirely, then had to fish it out with a probably inadequately-sanitized pair of tongs. I had sanitized only the probe, not the gauge, and since I normally use it when steaming milk for espresso drinks I was worried about milk-related bacteria.

- The two pot method worked OK, but it would be better to have a larger one. Bummer; I thought I had finally found a use for the 16 quart All-Clad!

- Pay attention to the orientation of the lid on the fermenter so that the airlock does not interfere with the bucket handle.

- Use more suitable thermometers. Candy thermometer doesn't go below 100, and the steamed milk thermometer is too short to be convenient. Plus, I tend to drop it. A floating thermometer might be perfect for the wort.

- Try the wort chiller next time to see if building one is worthwhile. The ice water in the sink isn't a terrible hassle but the freezer doesn't make enough ice for this. Would need to get some bagged ice in advance.

- I'm seeing conflicting information on whether it's good to use the straight tap water. Might want to boil and chill it in advance next time.

- Used Five Star cleaner and sanitizer.

- 2.5 gallons of water takes about 25 minutes to bring to boil on high heat.

- The boilover risk seemed momentary. When the hops are added it goes nuts! After stirring it dies down quickly and isn't a problem once boiling steadily.

- The spent grain is very tasty! I ate a few spoons full. It's contains the hulls, which I will no doubt discover are indigestible, but they are soft enough to chew.

6 comments:

Before having a wort chiller I used distilled water -- cleaner than my tap water. Put it in the freezer a hour before starting the boil. After the boil the water is cold enough when combined with the hot wort to get you to pitching temp, or very close.

About adding hops... I read about a stepped approach to adding the bittering hops. Doing this is supposed preserve more of the hop flavor. Add hops in 3rd's throughout the boil.

When it comes time to add the finishing hops I do it after turning the heat off. By the time I get the wort chiller ready the finishing hops have been in the wort for about 5 or 10 mins. More of the hop flavor comes through this way.

Thanks!

Good tip on the hopping. I now see that Palmer writes a bit (page 43 of 3rd edition) about how adding flavoring hops midway through the boil provides a compromise between isomerization of the alpha acids and evaporation of the aromatic oils. That makes sense to me. It seems like there may be a lot room to fine-tune the timing and amount of the additions in order to get the desired utilization for bittering along with the desired range of flavors. That kind of experimentation feels like it's a long ways away, but I'm looking forward to it.

You didn't say if you rinsed the speciality grains while in the muslin bag or not. Typically I don't use a muslin bag at all. After steeping the grains I strain and rinse through a very fine 10" mesh strainer. I am always amazed after steeping how much more color and flavor can be extracted from the grains.

I did rinse while in the muslin bag. I see what you mean about a strainer, since I had to use one anyhow for rinsing. Might as well avoid the bag.

Have you ever eaten the spent grain? It is definitely still flavor-packed. I wish I had thought to sample the steeping liquid (does that have a name?).

I have eaten the spent grain. As you noted, it does digest very well. Have also mixed it in with brown rice and wheat bread dough. While I thought there might be some potential there, my family thought otherwise. Someday, I'll get back to that...

I'm not sure about a name for the steeped speciality grains, although I have referred to it as speciality grain "tea" whilst talking to other brewers and no one objected.

I was surprised how "dry" (not sweet) the speciality grain tea is. I shouldn't have been, but I was. Taste varies wildly depending on the grain. I love the finish on black patent and chocolate malts.

I once made a scottish ale with 120L crystal malt. Nice and smokey, reminiscent of Laphroaig.

Post a Comment